NanoEdge AI Studio V3

Unveil an innovation reshaping industries with cutting-edge AI solutions for intelligent and adaptable products.

Unveil an innovation reshaping industries with cutting-edge AI solutions for intelligent and adaptable products.

Quantum Leap's AI project redefines industrial efficiency through signal interpretation, proactive anomaly detection, and optimization. Unlock the potential of equipment signals for transformative results.

In the industrial landscape, equipment signals hold untapped potential. The challenge lies in deciphering these signals to optimize performance and detect anomalies before they escalate. Quantum Leap's project addresses the need for proactive solutions to enhance machinery efficiency and reduce downtime.

Quantum Leap introduces an innovative approach that harnesses Machine Learning to decode equipment signals. This enables real-time anomaly detection and operational optimization, reshaping how industries manage machinery and systems.

Our commitment to innovation drives us to tackle complex challenges head-on. The journey of our AI-Driven Equipment Optimization and Anomaly Detection Project began with a deep understanding of the critical role that equipment signals play in industrial operations. Our dedicated team of experts embarked on extensive research to decipher these signals and transform them into actionable insights.

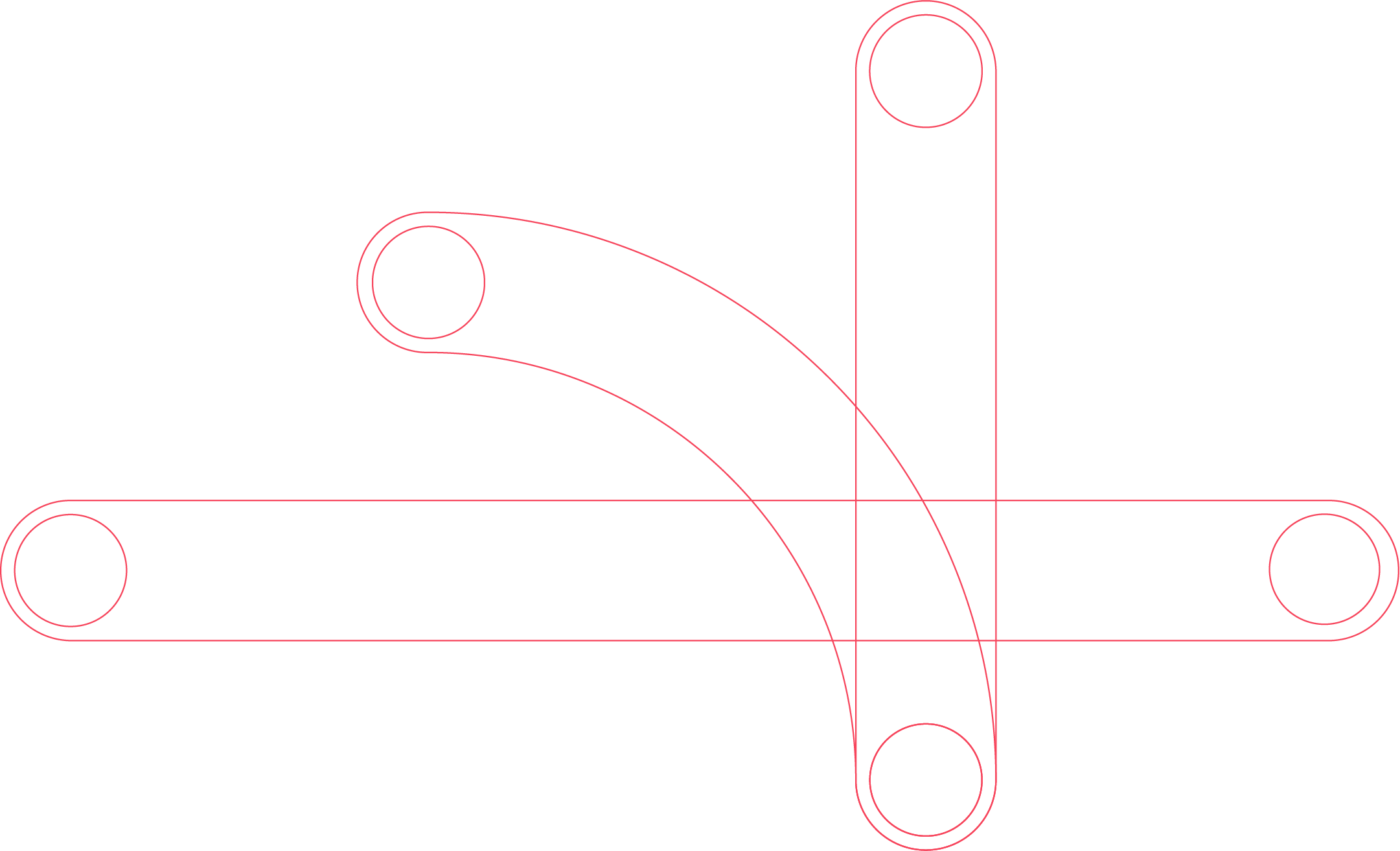

To address the challenge of decoding signals for proactive anomaly detection and operational optimization, we employed a multidisciplinary approach. Strategic sensor placement was a pivotal step, allowing us to capture real-time data from machinery. However, raw data alone wouldn't suffice. This is where Machine Learning comes into play. Our experts developed advanced algorithms that learned and recognized patterns from the captured signals. These patterns, often imperceptible to human observation, revealed the machine's normal functioning behavior.

Once our Machine Learning models were trained to understand what constitutes "normal," they became adept at spotting deviations from the established patterns. These deviations are indicators of anomalies or potential failures. By analyzing the evolution of vibration patterns, fluctuations in performance, or any other signal variations, our system could identify anomalies at their nascent stages. This approach doesn't just detect issues; it empowers industries to take proactive measures, preventing costly downtimes and maximizing operational efficiency.

In the realm of industrial machinery, our innovative process marks a new chapter in the way businesses manage equipment. By merging sensor technology and Machine Learning prowess, Quantum Leap redefines operational reliability and optimization. The result? A seamless synergy of technology and industry expertise that transforms equipment signals into actionable insights.

Discover the untapped potential of machinery signals and how they offer insights into performance and anomalies.

Explore how our methodology optimizes machinery operations, boosting efficiency and reducing maintenance expenses.

Learn how Quantum Leap's approach facilitates the early identification of anomalies, preventing costly downtimes.

See how our innovative approach, demonstrated with a fan motor application, can be adapted to diverse industrial machinery.